Cheap catalytic converter produced by Toyota

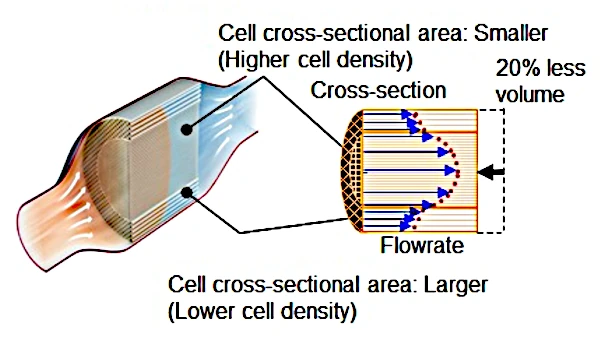

Toyota manufactures a smaller catalyst that employs 20 percent less precious metal in roughly 20 percent less volume, all while upholding the same exhaust gas purification capabilities. This design marks the world’s first integrally-molded Flow Adjustable Design Cell (FLAD®) substrate, featuring distinct cell cross-sectional areas between the inner and outer portions. Groundbreaking design and manufacturing techniques have facilitated the mass production of this new catalyst, which will gradually be integrated into Toyota and Lexus vehicles.

Addressing Challenges in Catalytic Converter Production

The increased use of catalytic precious metals for exhaust gas cleanup and air pollution reduction presents numerous challenges, including escalated costs and resource depletion. Toyota has undertaken extensive research and development to address these issues, focusing on enhancing the purification efficiency of catalytic precious metals. This includes optimizing substrate shape and length, as well as adjusting cell wall thickness and cross-sectional area. Other R&D endeavors involve selectively washcoating precious metals and catalytic materials, along with modifying catalytic substrate cell density to align with exhaust gas flows.

Collaborative Development with Denso Corporation

Toyota and Denso Corporation collaborated to develop the new FLAD® substrate to enhance the uniformity of exhaust gas flow. Through rigorous validations using simulations and prototype substrates, both companies succeeded in improving the exhaust gas flow uniformity within the catalyst. This was achieved by optimizing factors such as the ratios of cross-sectional areas of cells at the inner and outer portions and their corresponding densities. Consequently, with this advancement, approximately 20 percent less precious metal is utilized in a more compact catalyst that occupies roughly 20 percent less volume, while maintaining equivalent exhaust gas purification performance to conventional catalysts. Moreover, the newly developed innovative design and manufacturing technologies have enabled the mass production of the world’s first integrally molded catalyst.

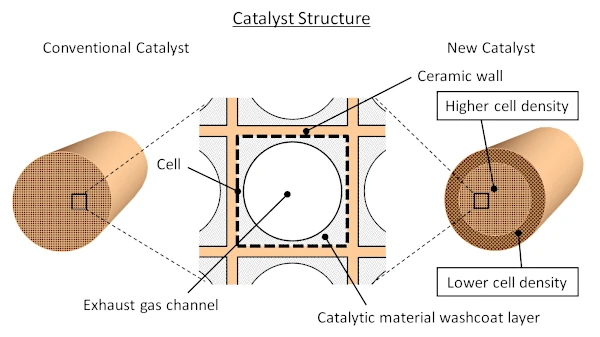

Comparative Catalyst Structures

Catalyst Structure

Conventional Catalyst

- Uniform cross-sectional area of each cell (uniform channels for exhaust gas)

New Catalyst

- Smaller cross-sectional area of cells at the inner portion (narrower channels for exhaust gas), with higher cell density

- Larger cross-sectional area of cells at the outer portion (wider channels for exhaust gas), with lower cell density

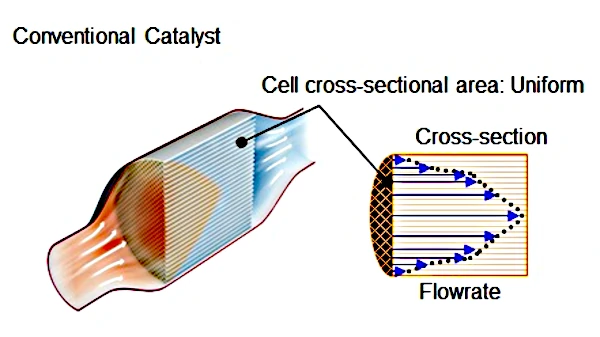

Understanding Catalytic Converter Functionality

Currently, the most widely used substrate in exhaust gas purifying catalysts for gasoline engines is ceramic (cordierite), featuring a honeycomb structure composed of square or hexagonal cells. These cells' walls are washcoated with catalytic materials such as platinum (Pt), rhodium (Rh), palladium (Pd), and other precious metals, providing a catalytic effect to purify harmful gases like carbon monoxide (CO), unburned hydrocarbons (HC), and nitrogen oxide (NOx) within the exhaust, making it safer.

Optimizing Exhaust Gas Flow

While conventional catalysts have a uniform cell cross-sectional area, the newly developed FLAD® substrate features a structure with different cell cross-sectional areas between the inner and outer portions. Toyota has successfully achieved mass production of this substrate using the world’s first design and manufacturing technology capable of integrally molding the catalyst.

Balancing Exhaust Gas Flow

Flow of exhaust gas within the catalyst

Conventional Catalyst

Exhaust gas flow concentrated at the inner portion

New Catalyst

Improved uniformity of exhaust gas flow through different cell cross-sectional areas in the inner and outer portions

Uniform exhaust gas flow within catalysts installed in exhaust pipes enables the effective purification of exhaust gas by the washcoated precious metals and other catalytic materials. However, the use of conventional substrates with uniform cell cross-sectional areas results in an imbalanced flow of exhaust gas because the gas flow through the inner portion of the catalyst is faster and at a higher volume than that through the outer portion. Consequently, more catalytic precious metal is required at the inner portion of the catalyst to maintain purification performance. Current catalytic material washcoating technologies require all cell walls to be coated equally during the washcoating process, resulting in parts of the catalyst with a lower exhaust gas flow rate being coated with the same amount of catalytic precious metals as those parts with a higher flow rate.