Exploring a broken Rear Muffler and Two Resonators: Construction Analysis

Introduction:

In the world of automotive exhaust systems, understanding the components and their integrity is essential for maintaining optimal performance and ensuring safety. In this article, we delve into the examination of a deteriorated rear muffler and two resonators from a single vehicle, shedding light on their construction and the damage they sustained over time.

Description of Damages:

The rear muffler and resonators under scrutiny were part of an aftermarket exhaust system that had been in use for several years. The exhaust pipes did not exhibit significant corrosion, especially in comparison to other parts of the exhaust system. The whole exhaust system was made of aluminized black steel.

Small Resonator (Front):

Small Resonator Broken Pipe Inside

The small resonator, positioned immediately after the manifold pipe, initially began to show signs of damage in the form of cracks on the sidewalls due to engine vibrations. After welding repairs, it managed to withstand further use for a few more years before the exhaust pipes entering the resonator broke at the welding point. Corrosion was the primary culprit, accelerating rapidly at the weld due to the absence of an effective anti-corrosion coating and exposure to high temperatures. Additionally, internal perforated tubing deteriorated due to vibration-induced stress.

Large Resonator (Middle):

Large resonator with two chambers

The large resonator, both externally and internally, displayed minimal corrosion. However, the most significant concentration of corrosion was once again found at the junction where the exhaust pipe connected to the resonator. In this instance, the inlet pipe detached at the welding seam.

Rear Muffler:

Rear muffler with fiberglass

However, the rear muffler exhibited the most extensive corrosion, both internally and externally. While the exhaust pipes leading to the muffler did not detach and showed surface corrosion, the lower section of the muffler suffered significant corrosion at the point where condensate from exhaust gases accumulated. Holes and defects in the muffler casing developed in this area. Additionally, internal baffles and tubes also corroded, resulting in significant deterioration beyond surface corrosion.

Rear muffler with broken chambers

Rear muffler with broken internal baffles

Construction Analysis:

Small Resonator (Front):

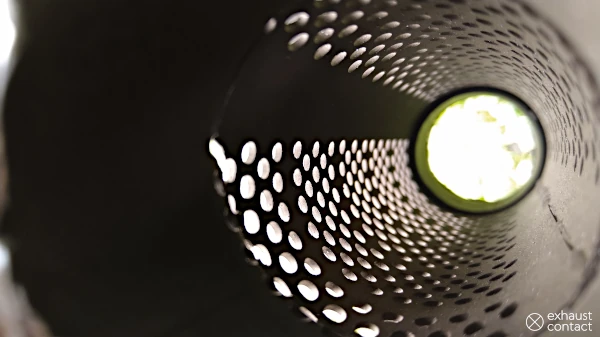

The interior of a small resonator pipe

The small resonator operates as a reflective muffler, with its effective damping range primarily spanning from 63 to 200 Hz, with a lesser effect in the 1600-2500 Hz range. Inside, it features a perforated tube through which exhaust gases flow. The casing is constructed from a single layer of aluminized sheet steel.

Large Resonator (Middle):

1 - absorptive chamber, 2 - reflective chamber

The large resonator is a combination of a reflective-absorptive muffler type. Inside, a perforated tube runs through two chambers: a reflective chamber and an absorptive chamber. The effective damping range of the absorptive chamber lies between 1000 Hz and 4000 Hz (high frequencies). Both chambers are identical, but the absorptive one is filled with sound-damping material, typically fiberglass.The two chambers are separated by a partition. The casing is constructed from two layers of aluminized sheet steel.

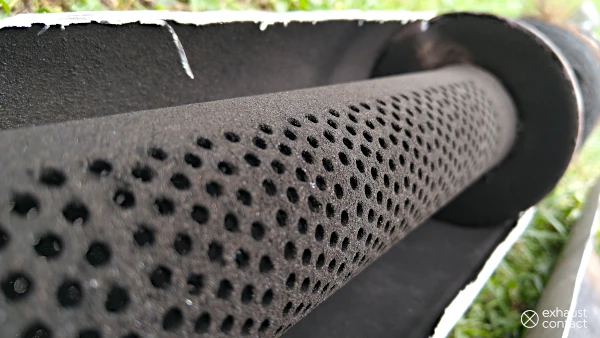

1 - perforated pipe, 2 - fiberglass

Large resonator with reflective chamber

The interior of a large resonator pipe

Rear Muffler:

1 - dissipative chamber, 2 - expansion chamber, 3 - absorptive chamber

The rear muffler is a mixed design, comprising three chambers. The first chamber functions as a dissipative muffler, featuring a sealed-end tube and holes in the baffle through which exhaust gases escape. These gases then move into the second chamber through two smaller openings in a partition wall with a smaller diameter than the tube. The second chamber is an expansion chamber designed to dampen effective mid-range frequencies. The third chamber is an absorptive muffler. The casing is constructed from a single layer of aluminized sheet steel, although some manufacturers may use a double-walled design.

Conclusion:

Analyzing the construction and damages of the rear muffler and two resonators emphasizes the critical role of material quality, anti-corrosion measures, and design in the longevity and performance of exhaust components. Regular inspection and maintenance of these parts are vital for vehicle safety and performance, ensuring that they can effectively manage exhaust gases and sound while withstanding environmental stressors.