What Are the Trends in the Design and Production of Exhaust Systems for Motorcycles?

Motorcycles are more than just a means of transportation; they are a way of life for many people. The design and performance of motorcycles are constantly evolving, and so are their exhaust systems. Motorcycle exhaust systems not only affect the overall sound of the bike but also play a crucial role in its performance. In recent years, several trends have emerged in the design and production of motorcycle exhaust systems. This article will introduce the latest trends in the design and manufacture of motorcycle exhaust systems.

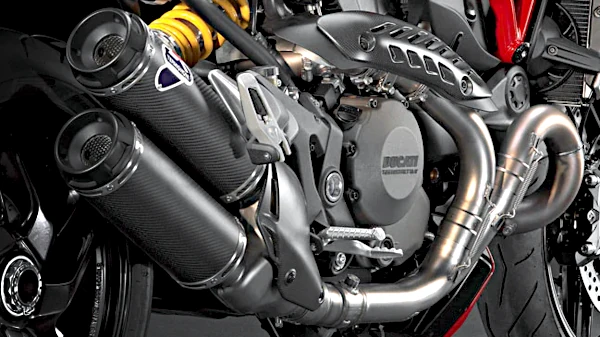

Use of High-Strength Materials

The use of high-strength materials such as Inconel, titanium, aluminum, and carbon fiber has become increasingly popular in the design of motorcycle exhaust systems. These materials are chosen for their strength, durability, and lightweight properties. Inconel, a nickel-chromium-based superalloy, offers high-temperature strength and corrosion resistance, making it an ideal material for exhaust systems. Titanium, known for its lightweight and high-strength properties, is often used in racing applications. Aluminum, being lightweight and offering excellent heat dissipation, is also a preferred choice for some exhaust components. Carbon fiber, an extremely lightweight and strong material, not only contributes to weight reduction but also offers excellent acoustic properties, influencing the exhaust note.

Use of Three-Dimensional Printing Technology

Three-dimensional printing technology has revolutionized the design and production of motorcycle exhaust systems. With 3D printing, designers can create complex shapes and structures that would be impossible to manufacture using traditional methods. The use of this technology allows designers to optimize the performance of exhaust systems by creating intricate internal geometries that improve exhaust flow and reduce backpressure. This, in turn, results in enhanced engine performance and fuel efficiency. Furthermore, 3D printing enables manufacturers to produce exhaust systems with lower weight and increased strength. By reducing the overall production time, it also allows for more cost-effective manufacturing processes.

Development of Electric Exhaust Systems with Valve Controlled by Pushbutton Application

The development of electric exhaust systems has been a significant trend in recent years, driven by the pursuit of improved performance and environmental sustainability. Electric exhaust systems are designed to offer not only enhanced power delivery but also reduced weight and better environmental performance compared to traditional exhaust systems. These systems typically use an electric motor to control the opening and closing of a valve, allowing the rider to adjust the exhaust note and performance of the bike. Some electric exhaust systems go a step further and offer push-button applications, enabling riders to switch between different exhaust modes, such as "sport" or "eco" modes, with the push of a button. This level of customization provides riders with greater control over their riding experience, tailoring the exhaust sound and power delivery to suit different riding conditions and preferences.

Integration of IoT Technology in Exhaust Systems

The Internet of Things (IoT) has permeated various industries, and motorcycle exhaust systems are no exception. The integration of IoT technology allows for enhanced monitoring and control of exhaust systems. IoT sensors can collect real-time data related to temperature, pressure, and gas emissions, providing valuable insights into the engine's performance. This data can be transmitted to the rider's smartphone or a dedicated dashboard, enabling them to stay informed about the exhaust system's condition and overall bike performance. Additionally, IoT-enabled exhaust systems can optimize their operations based on the data collected, leading to improved fuel efficiency and reduced emissions. The smart exhaust systems can also detect potential issues and notify riders or service centers for proactive maintenance, ensuring the longevity and reliability of the exhaust system.

Advancements in Noise Reduction Technology

While the distinctive roar of a motorcycle exhaust is beloved by many riders, noise regulations have become more stringent in various regions. As a result, manufacturers have been focusing on developing noise reduction technologies without compromising performance. Advancements in materials and engineering have led to the design of exhaust systems that offer improved noise reduction while maintaining a pleasing exhaust note. Baffles, resonators, and innovative muffler designs have been employed to attenuate noise levels without sacrificing power delivery. These advancements cater to riders who seek a more refined riding experience without attracting unwanted attention or violating noise restrictions in urban areas or noise-sensitive environments.

Exploration of Hybrid Exhaust Systems

The automotive industry has been exploring hybrid technologies, and this trend has also extended to motorcycle exhaust systems. Hybrid exhaust systems combine conventional internal combustion engines with electric powertrains, offering the best of both worlds. Such systems can improve fuel efficiency and reduce emissions by utilizing electric power for certain riding conditions, such as low-speed urban commuting or idling. The electric component can also enhance torque delivery at lower RPMs, providing smooth and responsive acceleration. On the other hand, during high-performance or highway riding, the internal combustion engine takes over, ensuring optimal power output. This hybrid approach allows for greater energy efficiency and reduced environmental impact while delivering an enjoyable and versatile riding experience.

Conclusion

In conclusion, the design and production of motorcycle exhaust systems are constantly evolving to meet the demands of riders, environmental regulations, and technological advancements. The use of high-strength materials, three-dimensional printing technology, and the development of electric exhaust systems with valve control by pushbutton application are some of the latest trends in the industry. Additionally, the integration of IoT technology, advancements in noise reduction, and the exploration of hybrid exhaust systems contribute to the continuous improvement of motorcycle exhaust systems. These trends aim to enhance the performance, weight, environmental impact, and rider experience, ultimately defining the future of motorcycle exhaust systems.