Types of Exhaust Flap Valves: A Comprehensive Overview

The automotive industry is constantly evolving, driven by the pursuit of improved efficiency, reduced emissions, and enhanced performance. Within this dynamic landscape, the role of exhaust flap valves has emerged as a critical component in achieving these goals. These innovative mechanisms play a significant role in controlling the flow of exhaust gases within internal combustion engines, impacting not only engine efficiency but also emissions and overall driving experience.

In this comprehensive overview, we delve into the various types of exhaust flap valves that have been developed to address the complexities of modern engine systems. From traditional solutions to cutting-edge dynamic control mechanisms, this article explores the diverse range of exhaust flap valve technologies and their functions. By understanding these different designs, engineers, enthusiasts, and automotive professionals can gain valuable insights into how these components contribute to the broader objectives of sustainable mobility and enhanced engine performance.

Join us as we journey through the world of exhaust flap valves, uncovering the intricate designs, mechanisms, and advantages that drive innovation in the realm of internal combustion engines.

Table of Contents: Types of Exhaust Flap Valves

- Bypass Flap Valves: Efficient Exhaust Gas Flow Regulation

- Understanding the Role and Advantages of EGR flap Valves in Emission Reduction

- Exhaust Flaps: Enhancing Braking Efficiency and Safety

- Back Pressure flap Valve: Enhancing Engine Efficiency and Emissions

- Exploring Passive Flap Valve Innovations in Modern Exhaust Systems

- Conclusion: Innovations and Harmonious Progress

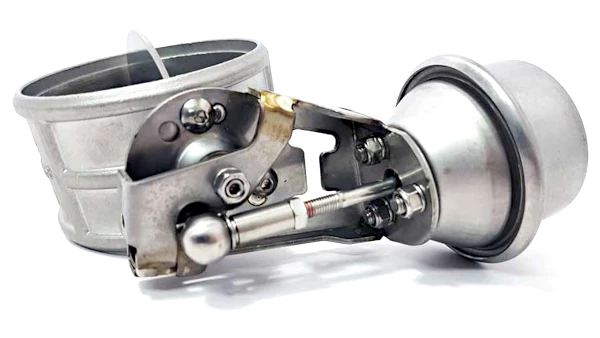

1. Bypass Flap Valves: Efficient Exhaust Gas Flow Regulation

Bypass flap valves play a pivotal role in optimizing exhaust gas flow within intricate engine systems. These valves are strategically designed to either open or close specific exhaust gas channels, providing precise control over the direction and volume of exhaust gases. Their implementation becomes crucial when an engine features multiple exhaust gas channels, requiring effective management for enhanced performance, efficiency, and sound control.

By incorporating bypass flap valves into the exhaust system, engineers enable the regulation of exhaust gas flow through the dynamic manipulation of individual exhaust gas pathways. This intelligent approach allows for fine-tuned adjustments that cater to varying engine conditions, resulting in improved combustion efficiency and reduced emissions.

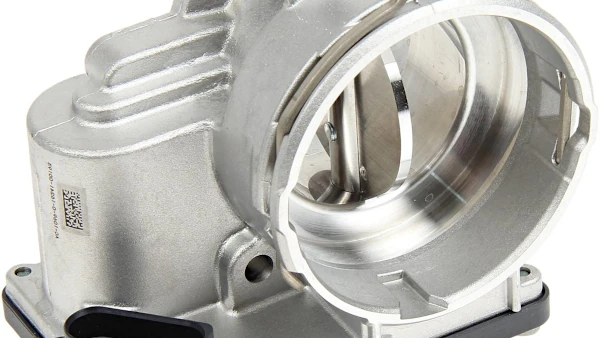

2. Understanding the Role and Advantages of EGR Flap Valves in Emission Reduction

The EGR flap valve, short for exhaust gas recirculation valve, plays a crucial role in the regulation of exhaust gas recirculation within internal combustion engines. By effectively managing the flow of exhaust gases, the EGR valve contributes to a significant reduction in nitrogen oxide formation and, subsequently, pollutant emissions.

The EGR valve operates by controlling the recirculation of exhaust gases back into the combustion chamber. This process leads to a decrease in combustion temperature, which in turn helps mitigate the formation of nitrogen oxides. This technology is especially vital for commercial vehicles aiming to meet stringent emissions standards.

One of the key features of EGR valves is their adaptability. These valves allow for precise adjustments of the EGR rate based on specific engine operating conditions. This individualized control ensures that the vehicle complies with legal emissions requirements, providing a sustainable solution for reducing pollutant output.

The activation of the EGR valve is achieved through a regulated actuator equipped with a position sensor. Depending on the implementation, this actuation can be accomplished using pneumatic, electrical, or hydraulic methods. Modern EGR systems integrate advanced electric actuators and high-performance compressed air cylinders, often equipped with distance measurement systems or position feedback mechanisms. This level of integration seamlessly incorporates the EGR valve into the overall engine management system.

Advantages of EGR valves include the efficient reduction of pollutant emissions in commercial vehicles. The ability to fine-tune the valve's operation according to various driving conditions ensures that emissions values remain within legal limits. Furthermore, advancements in actuator technology, such as electric actuators and precision feedback systems, enable optimal performance and control over the EGR process.

In conclusion, EGR valves play a vital role in reducing emissions from internal combustion engines, particularly in commercial vehicles. Their flexible and integrated design, coupled with the use of modern actuator technology, allows for effective management of exhaust gas recirculation and the achievement of sustainable emission reduction.

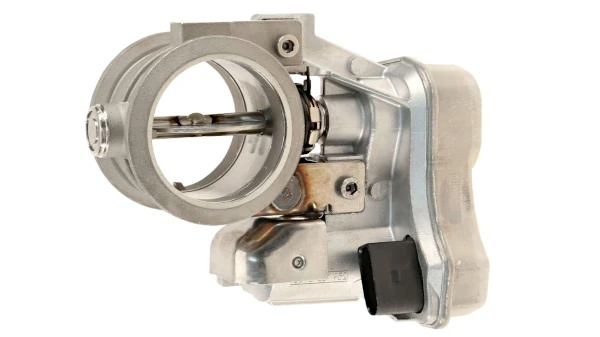

3. Exhaust Flaps: Enhancing Braking Efficiency and Safety

Exhaust gas brake flaps, also known as engine brakes, offer a unique and effective in-engine braking solution. By strategically manipulating the exhaust system using a throttle valve, coupled with the suspension of fuel supply, back pressure is generated within the engine, resulting in a controlled and desired braking effect. This technology not only contributes to efficient braking but also reduces wear on conventional wheel brakes, enhancing overall vehicle safety.

Modern high-performance exhaust flaps, some boasting power outputs of several hundred kW, have the capability to generate up to 85% of the brake energy required for utility vehicles. This translates to a remarkable brake horsepower of up to 100 kW. Moreover, exhaust flaps fulfill legal requirements for additional braking systems based on vehicle weight, offering an easily implementable and effective solution.

Application: Regulating Exhaust Flow with Precision

Exhaust flaps find versatile application in regulating the flow of exhaust fumes through simple opening and closing maneuvers. This function is predominantly achieved using pneumatic actuators, often without the need for a position sensor. However, the technology can also be harnessed with electrical actuators, showcasing its adaptability across various implementations.

Advantages of Exhaust Flaps

- Significant reduction of wear on conventional wheel brakes by distributing braking load

- Minimized maintenance costs and breakdowns associated with brake systems

- Prevention of the "fading effect," a decline in brake performance due to excessive heat

- Cost-efficient brake energy distribution in comparison to alternative brake systems

- Seamless integration with vehicle management systems, enabled by high-performance actuators

- Enhanced road safety through effective braking control

4. Exhaust Back Pressure Flap Valve: Enhancing Engine Efficiency and Emissions

The exhaust back pressure flap valve serves as a key component that shares similarities with an engine brake valve, albeit with a distinct purpose. Typically situated in the exhaust pipe, often positioned directly behind the exhaust gas turbocharger, the back pressure valve plays a vital role in optimizing engine performance. This becomes especially important as the automotive industry grapples with meeting stringent European emission standards, emphasizing the significance of particle filter regeneration.

The back pressure valve's primary function is to facilitate the regeneration of particle filters, an increasingly critical aspect in compliance with evolving European norms. Beyond this, the valve contributes to faster engine warm-up times and sustained engine warmth. This dual effect not only positively impacts fuel consumption but also leads to reduced exhaust emissions, making it a crucial mechanism for greener and more efficient engine operation.

Application in Diverse Vehicle Types

Exhaust gas back pressure valves find application across a spectrum of vehicles, encompassing both on-road and off-road utility vehicles, as well as industrial engines. The versatility of this technology allows it to fulfill various in-engine functions, ranging from gear shift support and particle filter regeneration to thermal management and cold start optimization.

Advantages of Variable Exhaust Gas Back Pressure

- Dynamic adjustment of exhaust gas back pressure settings

- Reduced fuel consumption and minimized exhaust emissions

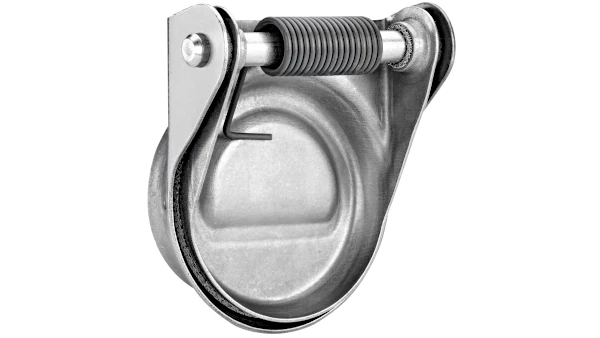

5. Exploring Passive Flap Valve Innovations in Modern Exhaust Systems

Introduction: Adapting Exhaust Systems in the Age of Hybridization

In the ever-evolving landscape of automotive engineering, the development of hybrid vehicles has brought about significant changes, including alterations to the architecture of exhaust systems. As the industry adapts to new technologies, the available space for traditional mufflers has diminished, necessitating innovative approaches to maintaining optimal acoustic performance while accommodating the limitations of space.

The Role of Passive Muffler flap Valves: Leveraging Physics for Performance

At the forefront of these innovations are passive muffler flap valves. These unobtrusive components play a pivotal role in refining the exhaust soundscape while adhering to the principles of fluid dynamics. Operating in harmony with the exhaust's inherent attributes—its flow, temperature, and pressure—these flap valves orchestrate a delicate balance of performance and efficiency.

Performance Enhancements and Acoustic Refinements

During low-flow conditions, such as at low engine speeds and loads, passive exhaust flap valves remain in a closed position. This strategic choice effectively mitigates the resonance of low-frequency sounds, providing a more comfortable auditory experience for passengers. Simultaneously, this design approach slightly elevates backpressure, contributing to overall engine efficiency.

Dynamic Response to Driving Conditions

As driving conditions change, so too do the roles of these flap valves. Under higher engine speeds and load conditions, when exhaust flow intensifies, passive flap valves gracefully transition to an open position. This shift facilitates increased exhaust flow, thus minimizing backpressure and ensuring optimal power output without compromising efficiency.

Engineering for Endurance: Challenges and Solutions

Positioned within the muffler, passive flap valves are subject to the harsh realities of the automotive environment. Enduring exposure to extreme temperatures, humidity, corrosive elements, and vibrations, these components showcase the marriage of engineering resilience and acoustic finesse.

Pioneering Automotive Harmony

In the realm of automotive innovation, passive exhaust flap valves stand as a testament to the industry's pursuit of harmonizing performance and acoustics. As hybridization continues to reshape the landscape, these unassuming flap valves ensure that the symphony of power and refinement resonates harmoniously with every drive.

6. Conclusion: Innovations and Harmonious Progress

Throughout this exploration of exhaust flap valves and related technologies, the automotive industry's commitment to harmonizing efficiency and acoustics is evident. As the automotive landscape continues to evolve, these unassuming components play a significant role in ensuring power and sophistication resonate seamlessly with every drive.

Contrasting Vacuum-Operated and Electronically Controlled Valves in Customized Exhaust Systems

Achieve the Perfect Sound: Universal Valved Muffler (Valvetronic) Options